Ⅰ. Overview:

LSL double-screw press master is mainly designed for the high temperature, high concentration and high efficiency extraction of chemical pulping black liquor, in particular the wheatgrass pulping. This system is featured in proper leak tightness, low pulp heat loss and high black liquor extraction yield. The extracted black liquor has higher temperature and concentration to create favorable conditions for the energy saving of alkali recovery and other black liquor treatment. In addition, the higher black liquor extraction yield reduces the water pollution of middle process and relieves the seriflux processing load of subsequent process. The working process is in such a way that the pulp is fed to the inlet of double-screw press master through the outlet of bin discharge port or high concentration hydrapulpter and pushed to the other end from one end through the rotation of double-screw shaft. In the pushing process, as the double-screw shaft pitch becomes smaller, the squeeze pressure applied to the pulp keeps increasing to force the black liquor of it to extrude and discharge from the filter opening. The concentration of pulp after black liquor extraction can be more than 38% and will be discharged through the outlet.

This equipment has simple structure, small floor area, easy handling and operational safety, which make it the ideal equipment for black liquor extraction.

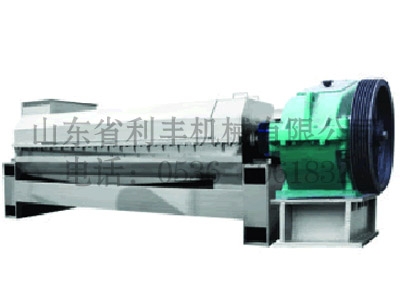

This machine mainly consists of screw shaft, frame, pulp inlet, filter drum, filter plate, reducer, coupling and speed regulation motor etc.

This machine is most suitable for the black liquor extraction of chemical or semi-chemical pulp with wood, bamboo, bagasse, rice, wheatgrass and reed as raw material. The extraction effect will be better if more machines are used in series.

Ⅱ. Technical Specification:

|

Model |

LSL-250 |

LSL-400 |

LSL480 |

LSL600 |

LSL700 |

|

Production capacity T/D |

20-40 |

40-60 |

60-80 |

120-160 |

240-300 |

|

Screw shaft dia. mm |

Φ250 |

Φ400 |

Ф480 |

Ф600 |

Ф700 |

|

Concentration of Feeding Pulp |

8-12% |

||||

|

Concentration of Outgoing Pulp |

35-40% |

||||

|

Reducer |

ZQ50-I |

ZQ65-I |

ZQ65-I |

ZQ75-I |

ZLY100-I |

|

Speed regulation motor |

YCT250-4B/ |

YCT315-4A/ |

YCT315-4B/ |

YCT-355-4A/ |

YCT355-4B/ |

|

External dimension mm |

3640×2000×1180 |

4102×2361×1230 |

4950×2450×1420 |

5500×2850×1490 |

5800×3350×1600 |

|

Weight kg |

3000kg |

5000kg |

5500kg |

7000kg |

8500 kg |