Ⅰ. Overview

It is the technical difficulty for waste paper regeneration to effectively remove the glue of the waste paper in an economic way, in particular for the imported waste box making paper (AOCC), 37# office waste paper and large ink point. Heat disperser is the widely used equipment to handle the adhesive foreign matters presently.

Our company introduces the overseas technology and adopts a series of patented technology to develop LPS series disc type heat dispersers, which are the indispensable equipment for the pulping and paper making with waste paper as raw material. This heat disperser effectively disperses and refines the soft and adhesive foreign matters and large ink point density of which is close to the fiber to enable more economic and effective production of high grade regeneration pulp. This equipment is featured in less fiber cutting, better dispersal, dispensing with millstone mill pulping and low operating cost etc.

Ⅱ. Main structure and working principle

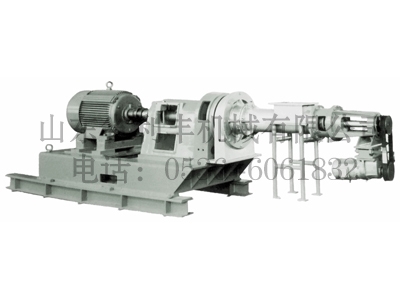

1. Main structure

LPS series disc type heat disperser mainly consists of feeding system, pulping, heat dispersion system and motor transmission system. The feeding system includes the feeding motor, feeding screw and feeding box etc. The pulping and heat dispersion system mainly contains the pulping chamber, dynamic and static grinding disc and adjusting and shifting unit. The motor transmission system includes the base, shaft sleeve and packing seal system, main drive motor and coupling etc.2. Working Principle

The pulp of 15% - 35% concentration is fed to the pulping chamber through the feeding screw and the high concentration pulp passes through the grinding disc to knead and disperse the pulp. The gap between the grinding discs is adjustable to allow the dispersion of various pulps. As the high speed discs can enhance the pulp temperature quickly, it will disperse the heat of waste paper stock which contains a lot glue and ink.

Ⅲ. Equipment Features

1. LPS series disc type heat disperser adopts belt screw feeding and is featured in high concentration, low power consumption and less fiber tendering.

2. For many kinds of waste paper, LPS series disc type heat disperser can be used for the high concentration heat dispersion of various waste paper deinking pulp and box making paper waste paper pulp.

3. The discs of LPS series disc type heat disperser are made of hard alloy and are featured in wear resistance, corrosion resistance, ageing resistance and long service life.

4. As the pulping area is large and the tooth shape is specific, this heat disperser can have good heat dispersion for pulping and give certain brooming function for the fiber. The physical strength of paper made by this is enhanced to certain degree, such as the tearability, folding endurance and tensile strength etc.

5. As the perfect equipment for pulping and heat dispersion of modern paper making industry, this heat disperser structure is simple, easy to repair and low running noise.

Ⅳ.Main Technical Parameters

Main Technical Parameters

|

Specification / Parameters |

Production capacity T/D |

Pulping concentration (%) |

Main motor power (kW) |

Rotor speed (rpm) |

Feeding screw dia. (mm) |

Feeding motor power (kW) |

Feeding port dimension (mm) |

Discharge port dimension (mm) |

|

LPS-22 |

10-15 |

15-35 |

22 |

2940 |

Ф130 |

1.1 |

150×140 |

250×80 |

|

LPS -30 |

15-20 |

15-35 |

30 |

2950 |

Ф130 |

1.1 |

150×140 |

250×80 |

|

LPS-37 |

20-30 |

15-35 |

37 |

2950 |

Ф140 |

1.5 |

200×150 |

300×80 |

|

LPS-45 |

25-35 |

15-35 |

45 |

2970 |

Ф155 |

1.5 |

250×150 |

300×80 |

|

LPS-55 |

30-40 |

15-35 |

55 |

2970 |

Ф155 |

1.5 |

250×150 |

300×80 |

|

LPS-75 |

40-60 |

15-35 |

75 |

2970 |

Ф150 |

2.2 |

250×150 |

300×80 |

|

LPS-90 |

45-70 |

15-35 |

90 |

2970 |

Ф165 |

2.2 |

250×170 |

300×100 |

|

LPS-110 |

50-85 |

15-35 |

110 |

2980 |

Ф175 |

3 |

280×180 |

300×100 |

|

LPS-132 |

65-100 |

15-35 |

132 |

2980 |

Ф175 |

3 |

300×180 |

300×150 |

|

LPS-160 |

80-120 |

15-35 |

160 |

2980 |

Ф175 |

4 |

300×200 |

300×150 |

|

LPS-200 |

100-150 |

15-35 |

200 |

1480 |

Ф200 |

5.5 |

350×200 |

350×200 |

|

LPS -250 |

120-190 |

15-35 |

250 |

1480 |

Ф200 |

5.5 |

350×200 |

350×200 |

|

LPS-315 |

140-210 |

15-35 |

315 |

1480 |

Ф225 |

7.5 |

400×230 |

400×250 |